Compass Inspectors and Engineers have more than 10 year experiences working in the highly precision mechanical machining industry - CNC Machining, Lathing, Milling, Drilling, Grinding, Laser Marking, Engraving, Heat Treatment and Passivation. And material includes and not lmited to Aluminum, Stainless Steel, Die Steel, Tungsten Nickel Steel, Tungsten Nickel-Iron and Engineering Plastics. We're well exposed to high precision requirements and specifications of different industries such medical, electronics, semi-conductor, automotive and magnetic head industries. Machinery and Equipment. Compass team is capable to measure and inspect:

Mechanical and Precision Components and Parts

Mechanical and Precision Components and Parts Automotive Components

Automotive Components  Precision Mold and Tooling

Precision Mold and Tooling Plastic Injection Parts

Plastic Injection Parts

Welding

Welding Jigs, Tools and Fixtures

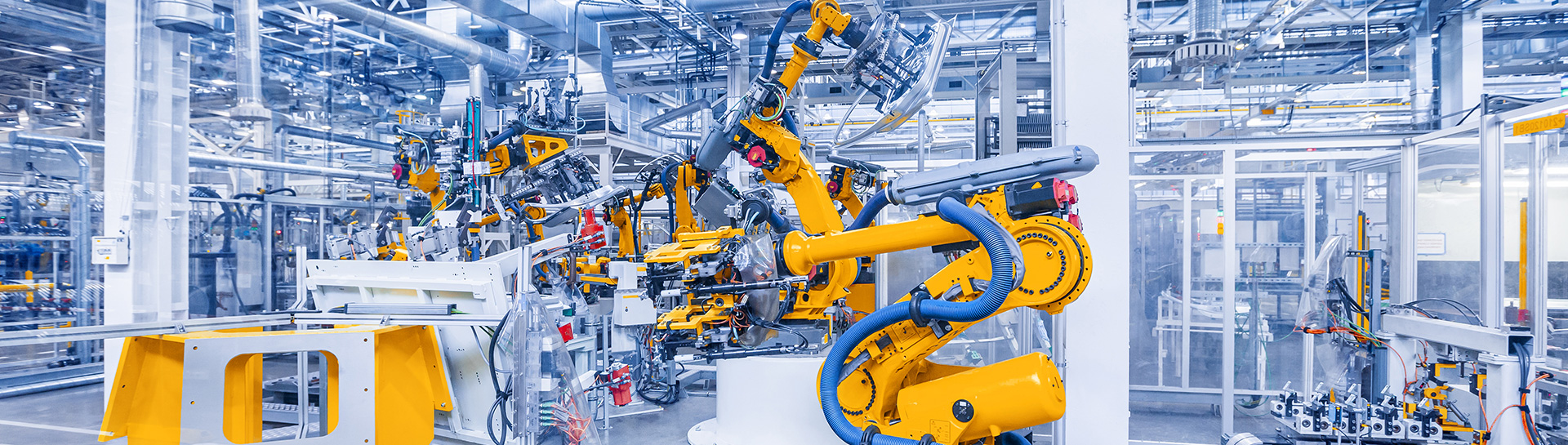

Jigs, Tools and Fixtures Machinery and Equipment

Machinery and Equipment Mechanical and Precision Components and Parts

Mechanical and Precision Components and Parts

This team previously worked in Scarborough / SAE Magnetics BU6 - Precision Jigs, Tools and Fixture and Customized Automation Equipment design, fabrication and assembly. And in 2003 the Scarborough team achieved a Good Suppper Award recognition from the SAE BU1 Manufacturing Engineering on remarkable Quarter Quality Review performance - Qualiy, On-Time, Speed & Service, with 3 consecutive quarter QQR Scorecard achieved above 80 points score.

Compass team is skilled to measure and inspect with:

CMM

CMM  Measuring Microscope

Measuring Microscope  Micrometer

Micrometer Roundness

Roundness Pin, Radius & Screw Gage

Pin, Radius & Screw Gage

Optical Profile Projector

Optical Profile Projector Height Gage

Height Gage Hardness

Hardness Others

Others

Compass team could execute and perform:

First Article Inspection

First Article Inspection  Cpk Dimensional Inspection

Cpk Dimensional Inspection  Measurement Error Analysis and Improvement

Measurement Error Analysis and Improvement  Dimensional Correlation

Dimensional Correlation  Gage R&R

Gage R&R